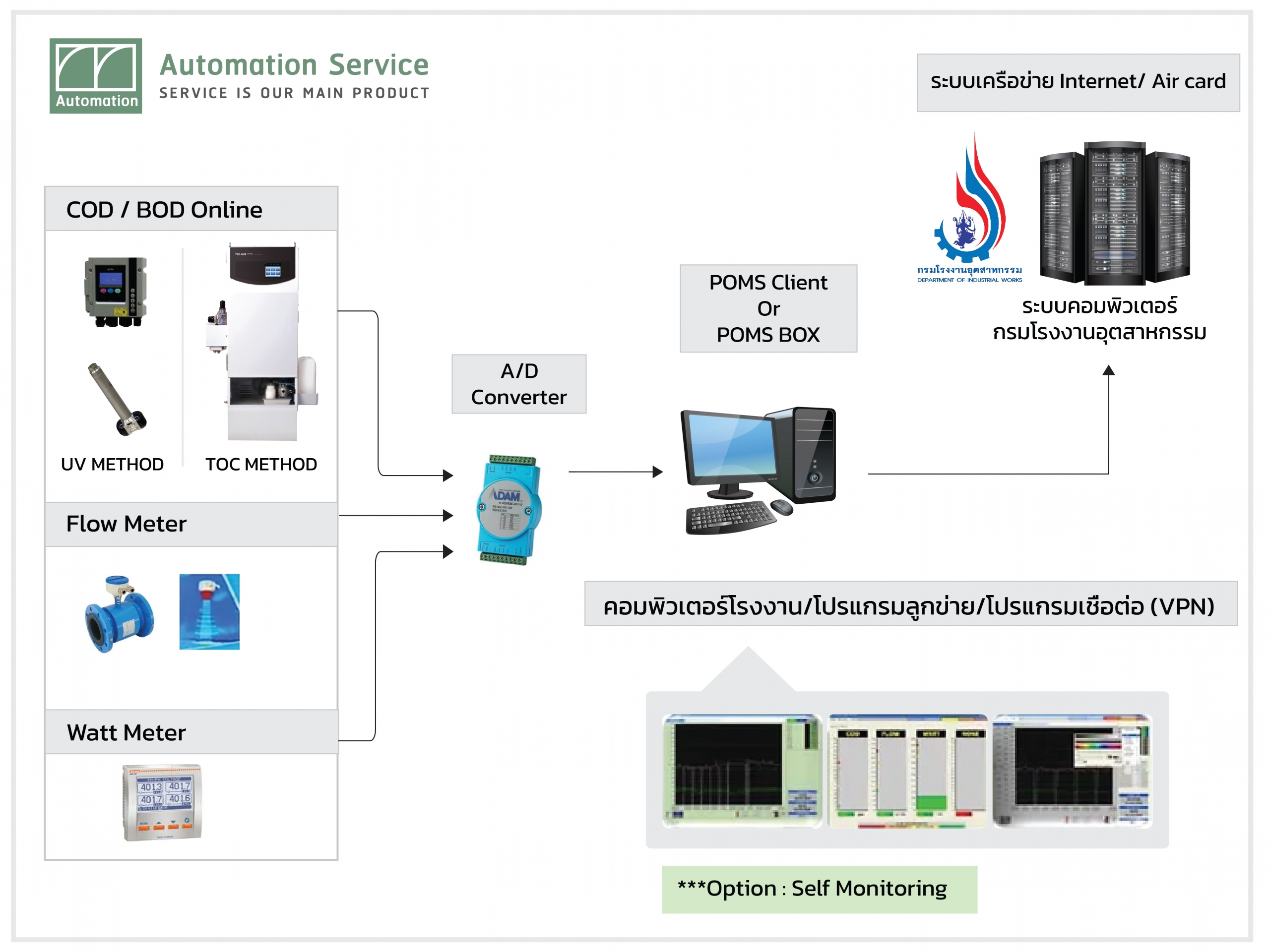

OnLine BOD-COD Pollution Monitoring System (OPMS)

ระบบตรวจสอบมลพิษระยะไกล

ติดต่อฝ่ายขาย คุณมนต์สินี

Tel : 094-565-3226

Line ID : @automationservice

ประกาศ/ ระเบียบที่เกี่ยวข้อง

เครื่องมือและอุปกรณ์ ที่โรงงานต้องจัดเตรียม

- 1เครื่องวัดซีโอดี/บีโอดี

- 2เครื่องวัดปริมาณการไหลของน้ำทิ้ง

- 3

เครื่องวัดปริมาณการใช้ไฟฟ้า

- 4

อุปกรณ์แปลงสัญญาณ

- 5โปรแกรมลูกข่าย/โปรแกรมเชื่อมต่อ (VPN)

- 6เครื่องคอมพิวเตอร์

- 7

ระบบเครือข่าย (Internet/Air card)

การเชื่อมต่อ COD/BOD Online กับระบบของกรมโรงงานอุตสาหกรรม

BOD-COD (UV METHOD)

MODEL OPM-1610

Specification (1)

**UV253.7 (254)nm is 5910B Standard method of The Examination of Water and Wastewater which suitable for COD

Specification (2)

Regression formula y = a + bx

y: COD (BOD) measured values (mg/L) by lab analysis

x: Measured value (Abs) by this product

a: Intercept

b: Regression coefficient (slope)

BOD-COD (TOC METHOD)

MODEL TOC-4200

TOC-4200: Features

Final effluent monitoring

- A substitute for the official analytical method (manual BOD/COD measurement) that permits automated, high-frequency measurements of organic pollutants in effluent.

- Measurements at a short measuring cycle (4 minutes minimum) rapidly capture dramatic changes in organic matter or abnormal effluent.

➔ Provides data for voluntary effluent management and report data agreed to by local government.

Total pollutant load control regulation applications (organic pollution load)

- Converting the measured TOC values into COD values allows applications to COD total volume control.

- TOC ⇒ COD conversion functions are installed as standard.

Wastewater treatment plant influent (upstream monitoring)

- Measurements at a short measuring cycle (4 minutes minimum) rapidly capture fluctuations in organic pollutants in influent. Contributes to load control and prevention of abnormal effluent outflow in treatment systems.

- A TOC analyzer can detect all organic substances. It captures organic pollutants missed by UV detectors.

- Permits measurement of up to 6 flow lines for precise monitoring of a treatment facility.

Plant water (washing water, cooling water, recovered water, boiler water, condensate, etc.)

- Permits continuous monitoring of all process water used in a plant.

- Measurements at a short measuring cycle (4 minutes minimum) rapidly detect malfunctions and accidents.

Monitoring of river water sampled at water purification plants and treated water (tap water)

- Monitoring of fluctuations in sampled water quality due to rain and feedback to treatment processes

- Monitoring of water quality problems upstream of sample inlet due to effluent discharge accidents

- Permits simultaneous monitoring of treated tap water

- Supports monitoring TOC Removal Rate based on EPA regulations

Diverse Applications:

Example of Upstream Monitoring

Covers a Wide Range from Pure Water to Heavily Polluted Water

Uses Shimadzu’s proven 680 °C combustion catalytic oxidation method

- Detects all organic substances, even in samples with suspended solids.

Measuring range from 5 mg C/L to 20,000 mg C/L (50× sample dilution)

- An option can be attached to support high sensitivity measurements to 1 mg C/L full-scale.

Permits TOC measurements that match a sample’s characteristics

- TOC measurement by acidify and sparg TOC also known as non-purgeable organic carbon (NPOC)

- TOC determination by difference between total carbon (TC) and inorganic carbon (IC)

TOC = TC – IC (requires option) - TOC determination by addition method of NPOC and purgable organic carbon (POC)

TOC = NPOC + POC (requires option)

Simultaneous TN measurements

- The TN measurement option permits TN measurements using the catalytic thermal decomposition–chemiluminescence method (measuring ranges: 0–1 mg N/L to 0–10,000 mg N/L).

Sampling Unit

From pure water to heavily polluted water

- The sampling unit for heavily polluted water incorporates a unique washing function and special operation sequences to control blockages and biological contamination. This reduces the maintenance frequency.

- The sampling unit for pure water restricts exposure of the sample to the environment and inhibits contamination of the sample from the environment.

Models are available to switch between up to 6 sample flow lines

- More economical as the need for multiple instruments is eliminated (reduced instrument and piping costs)

- Thorough internal and external washing reduces cross-contamination between flow lines

Sampling Unit: Multi-Stream Suspended Solids Sampling Unit

Support for samples with high suspended solids levels

- Incorporates a homogenizer equipped with a strainer.

- Automatic washing of liquid-contact parts.

⇒ Prevents blockage due to slime or algae build-up. - Separate sampling unit and pretreatment unit

⇒ Fewer parts requiring maintenance.

Handles up to 6 flow lines

Required sample flow rate: 10 L/min

Low-flow model available

- Required sample flow rate: 1 to 2 L/min

Sampling Unit: Multi-Stream Sample Switching Unit

Support for samples with low suspended solids levels

- Assuming measurements of purified water, a water sampler is installed to minimize exposure of the sample to air.

Handles up to 6 flow lines

Required sample flow rate: 1 to 3 L/min

Automatic Dilution Function, High-Salt Sample Combustion Tube Kit

Automatic dilution function

- TOC-4200 offers automatic dilution functions (×2 to ×50×) as standard.

- Dilution functions do more than extend the measurement range…

- When measuring an acid, strong alkaline, or inorganic salt sample that may damage the instrument or consumables, the effect can be alleviated by diluting the sample.

- TOC-4200 permits automatic dilution measurements, regardless of the measurement range.

Combustion tube kit for salinity samples

- When measuring samples with high levels of inorganic salt, such as seawater, the inorganic salt can accumulate inside the combustion tube and cause physical blockage or deterioration of the combustion tube. This kit extends the tube-replacement period approximately ten times as compared to a normal combustion tube.

Easy to Use

Color LCD Touch Screen

Easy operation by color LCD touch screen

- Intuitive operation

- Large-button design and pressure-sensitive touch screen permit operation while wearing gloves.

- The transparent front panel prevents operation when door is closed. Door key and software password offer security.

- Multi-language support (English, German, Japanese, Chinese)

Diverse Scheduling Functions

Simple schedule setup

- Simply setting the measured item, range, and measurement period for each flow line makes it easy to enter even complex measurement schedules.

Calendar

- The calendar simplifies scheduling for automatic calibration, instrument sleep function, control sample measurement, and catalyst regeneration (up to 14 weeks).

- Batch inputs can be made by specifying a day of the week.

Management and Notification of Replacement Periods for Consumables

Management of replacement periods for consumables

- Management functions for replacement periods of consumables (reagents, etc.)

- Recommended replacement periods of consumables are evaluated from the operation status.

- By inputting the actual volumes, reagents can be managed according to the prepared reagent volumes.

Notification of replacement periods

- When the time to replace a consumable approaches, a pop-up window notifies the operator and gives instructions.

- Combining the contact outputs and other warning outputs simplifies consumables management.

Low Maintenance, Low Running Costs

Carrier Gas Purification and Saving Functions

Carrier gas purification function as standard

- Carrier gas purification function is installed as standard for 24-hour continuous operation by the online TOC analyzer. Purifying instrument or compressor air in a facility to produce carrier gas significantly reduces running costs.

N₂ carrier gas kit

- Compressed air is normally used as the carrier gas source but high-purity nitrogen gas can also be used as the carrier gas. Convenient when a nitrogen gas centralized pipe is available in a facility (optional).

Gas cylinder-adaptation (carrier gas saving function)

- A gas cylinder (high-purity air) can be used in facilities where no instrument air pipes or compressor are available.

- The carrier gas-saving function is provided because using gas from a cylinder increases the running costs. (Carrier gas can be saved more efficiently as the measurement interval increases.)

- Using the carrier gas-saving function in combination with the normal carrier gas purification function reduces the frequency of compressor maintenance.

TOC-4200 Flow Diagram

Comprehensive Conventional Communications Functions

Contact I/O, Analog I/O

Contact output

- 10 channels standard. Expand to 36 channels.

- Supported events are programmable.

Contact input

- Supports standard single flow line measurements.

- Expansion 1 supports measurements with contact control up to 3 flow lines.

- Expansion 2 supports measurements with contact control up to 6 flow lines.

- Supported events are fixed.

Analog output

- 2 channels standard. Expandable in 2-channel increments to 12 channels max.

- Select 4–20 mA or 0–16 mA output.

Analog input

- Supports 3 flow lines max. (optional).

- Dedicated flow inputs (for load calculations).

Enhanced Data Handling

Powerful Data Storage and USB Memory

Internal memory can hold:

- (1) 20,000 measured values

(approx. one year’s data at a 30-minute measuring cycle) - (2) History of 100 calibrations (weekly calibration over approx. two years)

- (3) History of 100 alarms

Saved data can be output to USB memory

- Data saved to USB memory in CSV format

- Use PC spreadsheet software to edit the data or to generate reports.

Site reference (1)

| Company | Parameter | Method | Location |

|---|---|---|---|

| AISIN THAI AUTOMOTIVE CASTING CO.,LTD. | COD/BOD | TOC AND UV | PRACHINBURI |

| BLCP POWER PLANT | COD/BOD | UV | RAYONG |

| BLCP POWER PLANT | COD/BOD | TOC | RAYONG |

| TENMA PAPER CO.,LTD | COD/BOD | UV | PATHUMTANI |

| DOW CHEMICAL | COD (3 SETS) | TOC | RAYONG |

| THAI POLYCABONATE CO.,LTD | COD | TOC | RAYONG |

| TOSTEM THAI CO.,LTD | COD (2 SETS) | UV | PATHUMTANI |

| บ. ผลิตภัณฑ์วีนไทย จก. | COD | UV | PATHUMTANI |

| โรงงานอุตสาหกรรมกระดาษบางปะอิน | COD | UV | AYUTTAYA |

| THAI POLYACETAL CO.,LTD. | COD (2 SETS) | TOC | RAYONG |

Site reference (2)

| Company | Parameter | Method | Location |

|---|---|---|---|

| YAKULT | BOD | UV | BANGKOK |

| YAKULT | BOD | UV | AYUTTAYA |

| PURAC(THAILAND)CO.,LTD | COD | TOC | RAYONG |

| THAI TINPLATE CO.,LTD | COD | UV | SAMUTPRAKARN |

| PHOENIX PULP AND PAPER | COD | UV | KHONKHAEN |

| PANASONIC (THAILAND) CO.,LTD | COD | UV | KHONKHAEN |

| Cho Heng Rice Vermicelli Factory Co.,Ltd. | COD/BOD | TOC | NAKHONPATHOM |

| BAYER PREMIER CO.,LTD. | COD (6 SETS) | TOC | RAYONG |

| DISIN (THAILAND) CO.,LTD | COD | UV | KHONKHAEN |

| MC TOWA SWEETENER CO.,LTD. | COD (2 SETS) | TOC | RAYONG |

Site reference (3)

| Company | Parameter | Method | Location |

|---|---|---|---|

| NISSAN AUTOMOBILE | TOC | COD (2 SETS) | SAMUTPRAKARN |

| NISSAN MOTOR | UV | COD (4 SETS) | SAMUTPRAKARN |

| THAI NOK CO.,LTD | TOC | COD | CHONBURI |

| PURAC (THAILAND) CO.,LTD | TOC | COD (2 SETS) | RAYONG |

| TOYOTA MOTOR (THAILAND) CO.,LTD | TOC | COD | SAMUTPRAKARN |

| TOYOTA MOTOR (THAILAND) CO.,LTD | UV | COD/ BOD | BANPHO |

| TOYOTA MOTOR (THAILAND) CO.,LTD | TOC | COD | BANPHO |

| TOYOTA MOTOR (THAILAND) CO.,LTD | TOC | COD (3 SETS) | GATEWAY |

| SINGHA BEER | UV | COD | NAKHONPATHOM |

| SINGHA BEER | TOC (PROCESS) | COD | NAKHONPATHOM |

Site reference (4)

| Company | Parameter | Method | Location |

|---|---|---|---|

| DENSO (THAILAND) CO.,LTD. | COD | TOC | CHONBURI |

| THAI TORAY SYNTHETICS CO.,LTD. | COD (2 SETS) | TOC | BANGKOK |

| POSCO THAINOX STAINLESS CO.,LTD. | COD (2 SETS) | TOC | RAYONG |

| THAI HONDA (LADKABANG) | COD | UV | BANGKOK |

| ISUZU MOTORS (THAILAND) CO.,LTD. | COD | TOC | SAMUTPRAKARN |

| THAI MMA CO.,LTD. | COD | TOC | RAYONG |

| PROSPER FOODS CO.,LTD. | BOD | UV | PRACHUABKHIRIKHAN |

| MANDARIN SPINNING CO.,LTD. | COD | UV | NONTABURI |

| THAI TAFFITA CO.,LTD | COD | UV | RAYONG |

| TUNTEX TEXTILE CO.,LTD. | COD | TOC | RAYONG |

| HOYA LENS | COD | UV | LAOS |

Site reference (5)

| Company | Parameter | Method | Location |

|---|---|---|---|

| SIAM MITSUI PTA CO.,LTD. | COD (2 SETS) | TOC | RAYONG |

| THAI PAPER MILL CO.,LTD. | COD/ BOD | UV | RAYONG |

| THAI FOOD CO.,LTD. | COD/ BOD | UV | SUPHANBURI |

| PTT CHEMICAL CO.,LTD. | COD | TOC | RAYONG |

| JFE STEEL GAVANITE CO.,LTD. | COD | UV | RAYONG |

| THAI RAYON PUBLIC CO.,LTD. | COD | UV | ANG THONG |

| YAN WAL YUN CO.,LTD. | COD | TOC | SAMUTSAKORN |

| PTT (R&D) – WANGNOI | COD/ BOD | TOC | AYUTTHAYA |

| ASIA SILICONES MONOMER CO.,LTD. | COD (2 SETS) | TOC | RAYONG |

| NIPPON STEEL GAVANIZE CO.,LTD. | COD | UV | RAYONG |

Site reference (6)

| Company | Parameter | Method | Location |

|---|---|---|---|

| SIAM MITSUI PTA CO.,LTD. | COD (2 SETS) | TOC | RAYONG |

| THAI PAPER MILL CO.,LTD. | COD/ BOD | UV | RAYONG |

| THAI FOOD CO.,LTD. | COD/ BOD | UV | SUPHANBURI |

| PTT CHEMICAL CO.,LTD. | COD | TOC | RAYONG |

| JFE STEEL GAVANITE CO.,LTD. | COD | UV | RAYONG |

| THAI RAYON PUBLIC CO.,LTD. | COD | UV | ANG THONG |

| YAN WAL YUN CO.,LTD. | COD | TOC | SAMUTSAKORN |

| PTT (R&D) – WANGNOI | COD/ BOD | TOC | AYUTTHAYA |

| ASIA SILICONES MONOMER CO.,LTD. | COD (2 SETS) | TOC | RAYONG |

| NIPPON STEEL GAVANIZE CO.,LTD. | COD | UV | RAYONG |